in Alignment

Parts and Tools

Application Search

Select your vehicle to find the

alignment parts you need

Part Number Search

Know your part number? Enter the

number here for more information

subpages

Certified Installers - Alabama

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Alabama Interested in becoming a certified installer - click here for more. |

|

Amigoz Tires

3464 AL 53 Huntsville, AL 35806 256-468-6173 |

Certified Installers - Washington

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Washington Interested in becoming a certified installer - click here for more. |

|

St. John, WA 99171

(509) 648-3480

|

Certified Installers - Kentucky

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Kentucky Interested in becoming a certified installer - click here for more. |

Certified Installers - Montana

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Montana Interested in becoming a certified installer - click here for more. |

|

Les Schwab

1100 Reeves Rd W Bozeman, MT 59718 (406) 577-2432 |

Certified Installers - South Carolina

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in South Carolina Interested in becoming a certified installer - click here for more. |

|

Florence, SC 29505

(843) 702-0105

|

Certified Installers - Kansas

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Kansas Interested in becoming a certified installer - click here for more. |

Certified Installers - Nevada

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Nevada Interested in becoming a certified installer - click here for more. |

|

Sunshine Service Brake and Alignment

850 S. Rock Blvd. Ste Sparks, NV 89431 775-358-5486 |

|

Greg’s Garage

410 E 6th St Reno, NV 89512 775 324-0911 |

|

Folbeck 4WD

Sparks, NV 89431 775-331-4177 |

Certified Installers - Oklahoma

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Oklahoma Interested in becoming a certified installer - click here for more. |

Vendor Menu (2)

- Category: subpages

- Friday, 29 March 2013 14:41

Vendor Information

International Purchase Order Addendum

Supplier Information and Capabilities - FM010

Supplier Evaluation and Risk Assessment - FM066

Temporary Deviation Authorization - FM036

Supplier FA Documentation - FM095

Supplier Quality Assurance Requirements - PL003

供应商质量保证要求 - Supplier Quality Assurance Requirements Chinese - PL003

MSS Documents

Certified Installers - Maine

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Maine Interested in becoming a certified installer - click here for more. |

|

Economy Auto Service

463 Pleasant St. Mechanic Falls, ME 04256 207-346-5926 |

|

Moody's Automotive

89 Stone Street Augusta, ME 04330 207-404-9574 |

Certified Installers - West Virginia

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in West Virginia Interested in becoming a certified installer - click here for more. |

|

(304) 473-7171

|

Quality and Safety

- Category: subpages

- Monday, 21 March 2011 16:47

Quality and Safety

|

Quality and Safety Programs We are proud to be registered as an IATF 16949 company. This registration is just part of our ongoing commitment to quality and service. IATF 16949 is the international automotive quality standard that is based on the popular ISO 9001 standard used by most industries around the world. SPC is audited by SAI Global, a world-wide registrar of quality, environmental, and industry standards. Specialty Products has been recognized by CSU's Health & Safety Consultation Services as one of the safest companies in Colorado by Achieving and maintaining SHARP certification since 2005. For additional information on our Quality and Safety Programs contact our Quality Services Manager at extension 4904. Click here for a copy of our ISO 9001 Certificate

Click here for a copy of our IATF 16949 CertificateClick here for a copy of our SHARP (Safety and Health Achievement Recognition Program) Certificate |

Safety Safety Data Sheets are an essential component of the GHS and provide comprehensive information about a substance or mixture for use in workplace chemical management. 85130 & 85774 - Cool Tool Fluid |

Thank You New Customer

- Category: subpages

- Friday, 21 February 2014 17:53

Thank you for your submission. We will contact you if we need any additional information.

If you have any questions please call 800-525-6505.

Tech Tips

- Category: subpages

- Wednesday, 22 July 2020 14:28

Tech Articles

|

Our in-house technicians have decades of experience and have seen thousands of vehicles. While SPC does not offer direct on-site service of vehicles, let their knowledge save you time and money, or just become more knowledgeable about the alignment field in general. Check out the articles below, or check out our Tech Tips Videos here.

|

Chief Niwot

- Category: subpages

- Wednesday, 06 October 2010 15:24

The origin of our logo and Chief Niwot

|

Some have asked about SPC's logo depicting a Plains Indian profile wearing a war bonnet or headdress. We are incorporated as Niwot Corporation dba Specialty Products Company to honor Chief Niwot also known as Chief Left Hand. Chief Niwot was a tribal leader of the Southern Arapahoe people and our corporate logo today honors the peace seeking leader who was uniquely qualified to guide his people in a tumultuous time. His ability to speak Arapahoe, Cheyenne, and English as well as his reported physical stature gave his culture the best opportunity to survive the waves of gold rush prospectors and then settlers coming to the Front Range of the Rocky Mountains. Sadly, Chief Niwot and some 180 other Arapahoe and Cheyenne people lost their lives in the Sand Creek massacre in 1864. This massacre ultimately led President Lincoln to call for a congressional investigation that resulted in the removal of Governor Evans from office and Colorado being placed under martial law.

To read more about Chief Niwot and the life of the Arapahoe people in Colorado and this important part of the history of our state, you can start at Wikipedia, Chief Niwot. You may also be interested to read ‘Chief Left Hand: Southern Arapahoe’ by Margaret Coel. Chief Niwot left an enduring legacy in the Boulder Valley and the State of Colorado.

|

New Part Request (2)

- Category: subpages

- Monday, 13 December 2010 17:49

|

Specialty Products is always looking for suggestions from the field. Do you have a vehicle that is out of alignment but there aren't any parts available to fix the problem? Fill in the form below to let us know what you are working on and what parts you need to do the job right! {loadformmaker 26} |

|

New Part Request

- Category: subpages

- Monday, 13 December 2010 17:49

|

Specialty Products is always looking for suggestions from the field. Do you have a vehicle that is out of alignment but there aren't any parts available to fix the problem? Fill in the form below to let us know what you are working on and what parts you need to do the job right! {loadformmaker 24} |

|

Boxtop Program

- Category: subpages

- Thursday, 06 January 2011 18:55

|

You can get SPC Gear, Visa Gift Cards, and more - and be entered into our quarterly $250 Visa Gift Card contest plus our Grand Prize - a trip to SEMA for 2. How? Collect SPC Boxtops!

|

Certified Installers - Maryland

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Maryland Interested in becoming a certified installer - click here for more. |

|

Top Gear Auto Shop

2310 N. Howard Street Baltimore, MD 21218 410-889-3131 |

SPC Gear

- Category: subpages

- Friday, 29 March 2013 14:41

SPC Gear

|

SPC Performance Golf Shirt High quality cream colored shirt with SPC Performance red logo embroidered on the front. 63000M - Medium 63000L - Large 63000XL - XLarge 63000XXL - XXLarge |

|

|

SPC Traditional Golf Shirt High quality black golf shirt with our traditional 'Indian Head' logo embroidered on the front. |

|

|

63007 | Performance Ball Cap Great looking ball caps with SPC Performance embroidered on the front.SPC Navy hat - Mid Profile - Red/White Logo - One size fits all |

|

63012 | SPC Retro Bar Stool This custom backless bar stool is a perfect addition to any shop. 30” high with chrome legs and an Specialty Product Company logo imprinted on the vinyl seat. |

|

SPC Performance Logo Jacket This jacket is great for light outdoor wear embroidered with our SPC Performance logo. 100% polyester woven shell bonded to a water-resistant laminated film insert and a 100% polyester microfleece lining. |

|

|

|

SPC Traditional Logo Jacket This jacket is great for light outdoor wear embroidered with our SPC Indian Chief logo. 100% polyester woven shell bonded to a water-resistant laminated film insert and a 100% polyester microfleece lining. |

|

|

66015 | SPC Safety Glasses Popular safety glasses with wraparound lenses. • Frameless, anti-scratch lenses for optimum vision • Guaranteed non-slip fit • 99.9% UV protection • Meets ANSI Z87.1+ |

|

SPC Mechanic's Gloves Gloves with a synthetic leather palm and Spandex padded top for form-fitting durability, featuring reinforced thumb, index finger and fingertips with contact points for improved handling of objects. |

|

|

SPC Traditional Logo T-Shirt Heavy duty t-shirt with our Indian Head logo printed on the front. |

|

|

SPC Performance T-Shirt SPC Performance 'tee' in a dark heather grey with a modern SPC Performance logo and vehicle graphic on the front. |

|

| 67001 | SPC Performance Cut Vinyl Vinyl stickers that proclaim you have the best in performance alignment. These stickers look great whether you use them for your windshield, side window or just to put on your tool box.Dimensions67001 White cut vinyl 2" x 6" |

|

| 67002 | Red on White SPC Performance Decal Vinyl stickers that proclaim you have the best in performance alignment. These stickers look great whether you use them for your windshield, side window or just to put on your tool box.Dimensions67002 Red printing on White Base - 1.5" x 5" |

|

| 67008 | Performance Bumper Sticker Vinyl stickers that proclaim you have the best in suspension parts. These stickers look great on your bumper or tool box! |

Thank You Submission

- Category: subpages

- Friday, 21 February 2014 17:53

Your Thank You Card has been delivered -

At SPC there is no limit on your opportunities to say THANKS. Did someone just help you finish a task so the order got out the door on time? Have you noticed that someone is putting in some ‘extra effort’ that is helping out an entire department? Did

someone offer a suggestion that saved you extra effort? Now you can spread the THANKS with just one little card.

Give 1, Give 10

The opportunity to share your appreciation is easy and fun!

Need to send another card? Click Here

Certified Installers - Newfoundland - Labrador

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Newfoundland - Labrador Interested in becoming a certified installer - click here for more. |

Certified Installers - Iowa

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Iowa Interested in becoming a certified installer - click here for more. |

|

Murray, IA 50174

(641) 447-3232

|

Certified Installers - Florida

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Florida Interested in becoming a certified installer - click here for more. |

|

Georges Wholesale Tire

3260 N. Lecanto Hwy. Beverly Hills, FL 34456 352-527-1712 |

|

Suncoast Automotive

11728 US Hwy 19 Port Richey, FL 34668 727-857-6935 Famous Automotive

2560 Hwy 1 South Saint Augustine, FL 32086 904-203-1390 |

|

|

Certified Installers - Indiana

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Indiana Interested in becoming a certified installer - click here for more. |

|

Richmond, IN 47374

(765) 966-8181

|

Certified Installers - Oregon

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Oregon Interested in becoming a certified installer - click here for more. |

|

Weisner's Automotive

855 SE Reed Market Road Bend, OR 97702

541-388-1616 Precision ADAS Services Inc.

64415 Strickler Ave. Suite 118 Bend, OR 97701

541-241-7865 |

|

Automotive Outfitters

8324 SE Foster Road Portland, OR 97266 503-772-0654 |

Certified Installers - Wyoming

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Wyoming Interested in becoming a certified installer - click here for more. |

Vendor Menu

- Category: subpages

- Friday, 29 March 2013 14:41

Vendor Information

International Purchase Order Addendum

Supplier Information and Capabilities - FM010

Supplier Evaluation and Risk Assessment - FM066

Temporary Deviation Authorization - FM036Temporary Deviation Authorization - FM036

Supplier FA Documentation - FM095

Supplier Quality Assurance Requirements - PL003

供应商质量保证要求 - Supplier Quality Assurance Requirements Chinese - PL003

MSS-4.000-Q_General Interpretation and Process Note.pdf

MSS-4.004-A_Weld Section Test.pdf

MSS-4.014-A_Induction Hardened Steel Testing.pdf

MSS-5.002-A_Packaging Standard for Outside Processing.pdf

EZ Cam (2)

- Category: subpages

- Tuesday, 06 May 2014 22:13

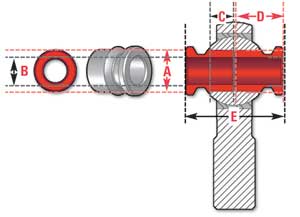

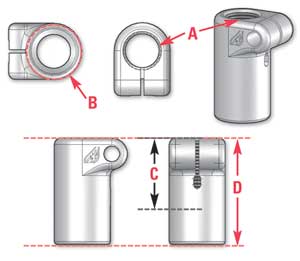

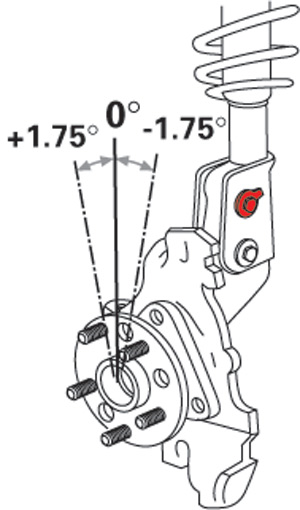

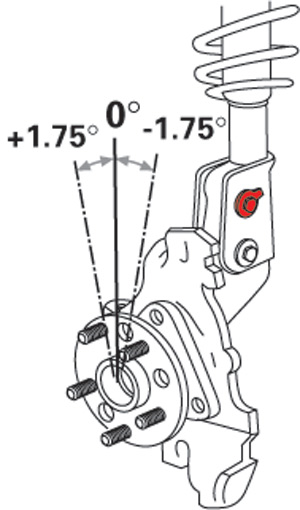

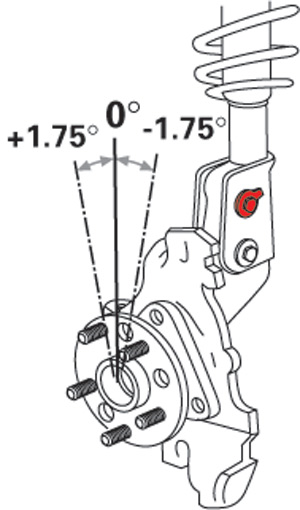

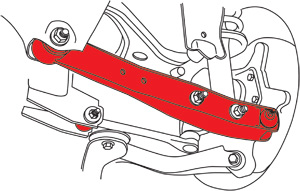

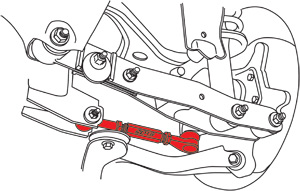

| EZ Cam XR™ - Part Nos. 81240, 81250, 81260, 81270, 81280, 81290, 81295 ------------------------------------- Make a two bolt strut adjustable up to ±1.75° camber with the EZCam™ from Specialty Products. Simply remove the upper bolt, install the EZCam, loosen the lower bolt, and dial in the required change. SPC's patented EZCams: Part No. 81250 - Pair For replacement of 12mm bolts Part No. 81260 - Pair For replacement of 14mm bolts Part No. 81270 - Pair For replacement of 15mm bolts Part No. 81280 - Pair For replacement of 16mm bolts Part No. 81290 - Pair For replacement of 17mm bolts Part No. 81295 - Pair For replacement of 18mm bolts Front Adjustment range: Camber ±1.75° Installation time: .4 hr/side Required: 1 kit per axle US Patent Nos. 8,544,861 B2 • 8,469,37 • Additional Patents Pending Check out our installation video for this part <iframe width="420" height="315" src="//www.youtube.com/embed/ugrwZZbnjn4?rel=0" frameborder="0" allowfullscreen></iframe>

|

|

Certified Installers - Hawaii

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Hawaii Interested in becoming a certified installer - click here for more. |

|

Lex Brode Tire

170 Wiwolle Street Hilo HI 96720

(808) 961-6001

|

Certified Installers Locator - Master Text Editor

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Find a Specialty Products Certified Wheel Alignment Installer near you! Click on the map below to find a Certified Wheel Alignment Installer in your area, or call customer service toll-free at 800-525-6505. Interested in becoming a certified installer - click here for more. |

|

|

International Certified Installers Chile |

Certified Installers - Chile

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Chile Instaladores certificados de alineacion de ruedas de productos especializados en Chile Interested in becoming a certified installer - click here for more. |

Certified Installers - Tennessee

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Tennessee Interested in becoming a certified installer - click here for more. |

|

Athens, TN 37303

(423) 507-9302

|

|

LaVergne, TN 37086

(855) 876-3864

|

|

Sparta, TN 38553

(931) 738-6060

|

Certified Installers - Illinois

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Illinois Interested in becoming a certified installer - click here for more. |

|

(224) 268-3111

|

|

Lake Barrington, IL 60010

(847) 381-1445

|

Proposition 65 Warnings

- Category: subpages

- Monday, 21 March 2011 16:47

Quality, Safety and the Environment

![]() WARNING: Cancer and Reproductive Harm - https://www.p65warnings.ca.gov/

WARNING: Cancer and Reproductive Harm - https://www.p65warnings.ca.gov/

Certified Installers - Delaware

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Delaware Interested in becoming a certified installer - click here for more. |

|

Newark, DE 19711

(302) 293-8627

|

Certified Installers - Arizona

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Arizona Interested in becoming a certified installer - click here for more. |

|

O'Haco Tire and Auto

501 Mike's Peak Street Winslow, AZ 86047 928-289-3611 |

Certified Installers - Utah

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Utah Interested in becoming a certified installer - click here for more. |

|

Spanish Fork, UT 84660

801-794-9385 BT Pearson Tire and Service 595 N. Bluff Street St George, UT 84770 435-628-0431 |

Certified Installers - Michigan

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Michigan Interested in becoming a certified installer - click here for more. |

Certified Installers - Pennsylvania

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Pennsylvania Interested in becoming a certified installer - click here for more. |

Certified Installers - Ontario

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Ontario Interested in becoming a certified installer - click here for more. |

Certified Installers - Ohio

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Ohio Interested in becoming a certified installer - click here for more. |

Certified Installers - Missouri

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Missouri Interested in becoming a certified installer - click here for more. |

Certified Installers - Nebraska

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Nebraska Interested in becoming a certified installer - click here for more. |

Certified Installers - Saskatchewan

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Saskatchewan Interested in becoming a certified installer - click here for more. |

Certified Installers - New York

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in New York Interested in becoming a certified installer - click here for more. |

Certified Installers - Texas

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Texas Interested in becoming a certified installer - click here for more. |

Certified Installers - California

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in California Interested in becoming a certified installer - click here for more. |

Certified Installers Locator - Canada

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Find a Specialty Products Certified Wheel Alignment Installer near you! Click on the map below to find a Certified Wheel Alignment Installer in your area, or call customer service toll-free at 800-525-6505. Interested in becoming a certified installer - click here for more. |

Certified Installers Locator

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Find a Specialty Products Certified Wheel Alignment Installer near you! Click on the map below to find a Certified Wheel Alignment Installer in your area, or call customer service toll-free at 800-525-6505. Interested in becoming a certified installer - click here for more. |

|

|

International Certified Installers Chile |

Certified Installers - Colorado

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Specialty Products Certified Wheel Alignment Installers in Colorado Interested in becoming a certified installer - click here for more. |

|

BG Automotive

1322 Webster Ave. Fort Collins, CO 80501 970-484-1443 |

|

BG Automotive

659 20th Ave Longmont, CO 80524 720-4684-6212 |

|

Denver Spring and Suspension

5171 Cook Street Denver, CO 80216 303-295-7638 |

|

Gallito Tires

1401 Main St. Longmont, CO 80501 720-684-6269 |

|

Goodyear Tire and Service

17226 South Golden Road Golden, CO 80403 303-278-7492 |

|

High Country Performance 4x4

1695 W. Hamilton Place Sheridan, CO 80110 303-761-7371 |

|

Lakewood Alignment

1575 Allison Street Lakewood, CO 80214 303-233-4681 |

|

Meining Automotive

1001 2nd Ave. Longmont, CO 80501 303-772-5919 |

|

Rocky Ford Discount Tire

1601 Elm Ave. Rocky Ford, CO 81067 719-254-3391 |

|

Ski Country Auto Repair and Towing

1125 N Summit Blvd Frisco, CO 80443 970-668-3093 |

|

Stang Auto Tech

7202 W 116th Ave Broomfield, CO 80020 303-404-3815 |

|

Stratton Car Care

110 New York Ave Stratton, CO 80836 719-348-5345 |

|

Stonum Automotive

1812 Sunset Pl Longmont, CO 80501 303-485-9303 |

|

Specialized Truck and SUV

761 Ten Mile Drive Frisco, CO 80443 970-352-7200 |

|

Tru Automotive

930 W. Mississippi Denver, CO 80223 303-954-8836 |

|

Weld County Garage/Truck City

1415 1st Avenue Greeley, CO 80631 970-352-7200 |

Certified Installers Locator - USA

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Find a Specialty Products Certified Wheel Alignment Installer near you! Click on the map below to find a Certified Wheel Alignment Installer in your area, or call customer service toll-free at 800-525-6505. Interested in becoming a certified installer - click here for more. |

Certified Installer Program

- Category: subpages

- Thursday, 06 January 2011 18:55

|

Customers - Find a Certified Wheel Alignment Installer in your area Installers - Specialty Products Certified Wheel Alignment Installer Program With our FREE online certification program, alignment techs can become an SPC Certified Installer. Developed by our ASE Master Certified technician, this program focuses on providing expertise in alignment aftermarket parts and installation procedures along with cutting edge problem solving. |

| Online Course The online course is comprised of a series of videos and quizzes designed to engage technicians while providing the latest information on alignment problem solving. This will help instill confidence in the installer and lead to better customer satisfaction as well as drive new customers to your shop. Click here to register and take the course at WheelAlignmentTraining.com (Note: You must register at WheelAlignmentTraining.com and meet the technician requirements to be able to take the free course and qualify for the certification program.) |

|

| Driving Customers After completing the course the technician and their shop will be featured in our online Certified Installer section. Potential customers will be able to look up installers in their area and be linked to your shop’s website. SPC will also direct questions from our tech and customer service lines to your shop when customers ask “Who can install these parts properly in my area?” |

|

|

Pride in Excellence

Get out the word that you are an SPC Certified Installer. After completing the course Specialty Products will provide the technician and shop with display items that promotes this achievement to your customers.

Certificate of Achievement You will receive a Certificate of Achievement that is suitable for framing and displaying in your customer waiting area. Certified Installer Banner Hang this 5 ft x 3 ft banner in the shop or above your bays. Durable, with corner grommets, this banner is a great way to promote your alignment expertise. Certified Installer Window Cling Place this 8.5” x 6.5” logo shield in your shop window to inform your customers that they have come to the right place for their alignment service. Have questions? You can contact our trainers directly to get more information on qualifying requirements, check on the status of your certification and more. Email them at: training@specprod.com |

|

Technicians applying for SPC Certified Installer must be currently certified as an ASE A4-Suspension and Steering technician or an approved equivalent.

Equivalent training examples:

– SPC Basic and Advanced In-House Training Combo

– SPC On-line training Courses 1 through 4.

– State issued Mechanic or Technician Certification

– Corporate Employee Suspension and Steering Training. (e.g. Les Schwab, Big O Tire)

– College or High School Suspension and Steering Classes. (Transcript required)

– I-CAR® Suspension and Steering Training

A copy all certifications will be required before SPC Installer Certification documents and display products are sent.

(“I”), a trainee, am voluntarily registering for training course(s) offered at or by Niwot Corporation d/b/a Specialty Products Company (“Company”). I am not, at any time, considered an employee of the Company and, therefore, am not a covered entity under Specialty Product Company’s Workers Compensation policy. I hereby indemnify and agree to hold the Company harmless from and against, any and all claims, expenses, actions or litigation, including the cost of defense of same, arising directly or indirectly on account of training cancellation, training content, or any injury on company location or in transportation to or from. I hereby consent to medical treatment at the nearest location in the event of injury, accident and/or illness during the training and understand that I am responsible and liable for payment of any medical claims, expenses, or losses that may occur as a result.

Warranty Policy (2)

- Category: subpages

- Friday, 02 October 2015 15:33

Purchasing Terms Addendum International

- Category: subpages

- Friday, 20 April 2012 01:50

PURCHASE ORDER TERMS AND CONDITIONS

International Addendum

- This order is to be shipped FOB origin.

- All delivery dates on this purchase order are dates product is required at Specialty Products Company, not shipping dates.

- Currency shown is in U.S. Dollars.

- Pricing shown is for part cost only.

- All freight is to be shipped freight collect via SPC Purchasing directed vendor and their agents.

- Invoices must be clearly marked with: “We hereby comply with U.S. marking regulations.”

- All parts must be packaged in a method that is designed to protect the shipment from any physical damage, rust or corrosion due to the shipping environment.

- Specialty Products Company shall be afforded the right to verify at the supplier’s or any subcontractor’s premises that contracted product conforms to specified requirements. Access to the supplier’s premises shall be made available during normal business hours with 24 hours notice or more. Access to any subcontractor’s premises shall be made available during normal business hours with 48 hours notice or more.

- A Manufacturing & Inspection Plan to the current drawing revision is required. All Subcontractors must be identified in the plan. Once approved, no changes to tooling, methods, or subcontractors may be made without written approval of Specialty Products Company. The inspection plan must cover all functional dimensions, all materials, heat treating, and finishes, and all test requirements. A final inspection report must be sent with the shipment which shows the results of the measurements and the number of pieces inspected. You may provide inspection data instead of a final inspection report if you prefer. As a minimum all dimensions marked “KEY” on Specialty Products Company drawings must be covered either by an inspection report or inspection data.

- Parts with drawings that refer to 3D scanning must be provided prior to shipment.

- Certifications are required for all Materials, Heat Treating, and Finish that are specified on the drawings. Test reports must also be supplied for any testing requirement specified in the drawing.

- NOTE: Packaging material must be in compliance with U.S. Customs phase II of the WPM Import Implementation Plan as of Sept 16, 2005.

- NOTE: No individual shipping carton may exceed 50 lbs. MAXIMUM gross weight. Failure to comply with this requirement will require a written Corrective Action and possible fees due to Corrective Action.

- NOTE: No individual shipping pallet or crate may exceed 2000 lbs. MAXIMUM gross weight. Failure to comply with this requirement will require a written Corrective Action and possible fees.

Revision Number 2 – 11/22/2019

Purchasing Terms

- Category: subpages

- Friday, 20 April 2012 01:50

PURCHASE ORDER TERMS AND CONDITIONS

By accepting this Purchase Order (hereinafter referred to as "the Order") the Vendor accepts the Terms and Conditions included herein, unless the Vendor notifies Specialty Products Company (hereinafter referred to as "the Buyer") of the Vendor's objections.

1. ACKNOWLEDGMENT AND ACCEPTANCE OF ORDER This Order constitutes an offer from the Buyer that is expressly limited to the Terms and Conditions contained herein. The Terms and Conditions of this Order are those that apply to the purchase of materials, items, products, components or services (hereinafter referred to as "Material"). All exhibits, attachments, technical specifications, drawings, notes, instructions, or information referenced in the Order are incorporated herein by reference. These Terms and Conditions control unless they are specifically varied or contradicted by one of the following methods in the listed order of precedence; 1.) Varying terms on the face of this Order, 2.) A current existing Master Purchase Agreement, 3.) Another valid contract between the Buyer and the Vendor to which this Order applies. All other prior oral or written statements varying the Order are specifically rejected and disclaimed.

2. CHANGES/AMENDMENTS The Buyer shall have the right at any time, by written notice, in the form of a Change Order, to the Vendor, to make any changes it deems necessary, including, but not limited to, changes in specifications, design, delivery, testing methods, packing or destination. If any such required changes cause an increase or decrease in the cost of or the time required for performance, an equitable adjustment shall be made in the contract price or delivery schedule, or both. Any claim by the Vendor for adjustment under this clause shall be deemed waived unless asserted in writing within ten (10) days from receipt by the Vendor of notice of change. Price increases, extensions of time for delivery and change in quantity shall not be binding on the Buyer unless evidenced by a form of Change Order issued and signed by the Buyer.

3. DELIVERY/FORCE MAJEURE If any Material is not delivered by the date specified herein, the Buyer reserves the right, without liability, to cancel this Order as to any Material not yet shipped or tendered, and to purchase substitute Material and to charge the Vendor for any loss incurred. Oral cancellation notices, made by the Buyer or the Vendor, are effective when made, but must be confirmed in writing. Any provisions hereof for delivery by installment shall not be construed as making the obligations of the Vendor severable. The Buyer shall have the right to refuse deliveries made more than one week in advance of any delivery schedule appearing in this Order unless arrangements for such early delivery have been confirmed with the receiving party.

The Vendor shall notify the Buyer in writing promptly of any delays (however caused) and of any actual potential labor dispute which delays or threatens to delay the timely performance of this Order.

If the Vendor is unable to complete performance at the time specified for delivery hereunder, by reason of strikes, labor disputes, riot, war, fire or other causes beyond the Vendor's reasonable control, the Buyer, at his option, may elect to take delivery of Material hereunder in its unfinished state and to pay such proportion of the contract price as the work then completed bears to the total work hereunder and to cancel this Order without liability as to the balance of the Material covered hereunder.

4. TITLE AND RISK OF LOSS Terms of shipping are F.O.B. the Buyer's delivery location unless otherwise noted within the terms of this Order.

5. PRICE/TAXES Prices stated on the Order hereof are firm and shall remain firm until deliveries have been completed unless otherwise expressly agreed to in writing by both parties. The Vendor agrees that any price reduction made with respect to Material covered by this Order subsequent to placement will be applied to this Order. All prices specified herein include all charges for, but not limited to, inspection, and packaging. Prices set forth are exclusive of applicable sales, use, excise, value-added or similar taxes. The Buyer is exempt from the Colorado’s Sales and Use Tax Law (state id number 21-02243) on items that it will be reselling. The Buyer will furnish the Vendor with a tax certificate upon request.

6. WARRANTIES The Vendor warrants that any Material supplied hereunder shall conform to the generally recognized manufacturing and safety standards of the Vendor's industry in the United States and shall meet or exceed the Vendor's specifications.

In addition to any other express or implied warranties, the Vendor warrants that the Material furnished pursuant to this Order will be: (a) free from defects in title, workmanship and material and clear of any liens and encumbrances; (b) free from defects in design except to the extent that such items comply with detailed designs provided by the Buyer; (c) of merchantable quality and suitable for the purposes, if any, which are stated on this Order.

If any material covered by this Order is found not to be as warranted, the Buyer may, by written notice to the Vendor: (a) rescind this Order as to such non-conforming Material; (b) accept such Material at an equitable reduction in price; (c) reject such non-conforming Material and require the delivery of suitable replacements.

If the Vendor fails to deliver suitable replacements promptly, the Buyer, with notice of five business days, may replace or correct such Material and charge the Vendor the additional cost occasioned the Buyer thereby, or terminate this Order for default.

Any items corrected or furnished in replacement are subject to all the provisions of this article entitled WARRANTIES to the same extent as items initially furnished or originally ordered.

Cost of replacement, rework, inspection, repackaging and transportation of such corrected Material shall be at the Vendor's expense.

This warranty provision shall survive any inspection, delivery, acceptance, payment, expiration or earlier termination of this Order and such warranties shall run to the Buyer, its successors, assigns, employees, students, and users of the Material. Nothing herein, however, shall limit the Buyer's rights in law or equity for damages resulting from delivery of defective goods or damage caused during the delivery of goods or provision of services.

Rights granted to the Buyer in this article entitled WARRANTIES are in addition to any other rights or remedies provided elsewhere in this Order or in Law.

7. INSPECTION AND ACCEPTANCE The Vendor shall inspect all Material prior to shipment to the Buyer. All Material covered by this Order may be inspected and tested by the Buyer or its designee. If the Buyer so elects to inspect or test successful completion of such inspection and testing shall be a prerequisite to the Buyer's acceptance of the Material. If deemed necessary by the Buyer, the Vendor shall provide without charge, all reasonable facilities and assistance for such inspection and test.

Any inspection records relating to Material covered by this Order shall be available to the Buyer during the performance of this Order and for such longer periods as specified by the Buyer. If any Material covered by this Order is defective or otherwise not conforming with the requirements of this Order, the Buyer may, by written notice to the Vendor: (a) rescind this Order as to such non-conforming Material; (b) accept such Material at an equitable reduction in price; (c) reject such non-conforming Material and require the delivery of suitable replacements; (d) accept shipment and receive credit for labor and materials consumed in the rework activity. If the Vendor fails to deliver suitable replacements promptly, the Buyer, with notice of five business days, may replace or correct such Material and charge the Vendor the additional cost occasioned the Buyer thereby, or terminate this Order for default. Cost of replacement, rework, inspection, repackaging and transportation of such corrected materials shall be at the Vendor’s expense. Additionally, Buyer costs for value added to defective Goods are recoverable from the Vendor. Buyer reserves the right to charge the Vendor an “Administrative Fee” of $ 250 per defective item following multiple product quality failures. No inspection (including source inspection) test, approval (including design approval) or acceptance of Material shall relieve the Vendor from responsibility for defects or other failures to meet the requirements of this Order. Rights granted to the Buyer in this article entitled INSPECTION are in addition to any other rights or remedies provided elsewhere in this Order or in Law. Buyer’s failure to inspect does not relieve Vendor of any responsibility to perform according to the terms of this purchase order.

8. BUYER'S PROPERTY IN SELLER'S POSSESSION All tools, special dies, molds, patterns, jigs and any other property furnished to the Vendor by the Buyer or specifically paid for by the Buyer for use in the performance of this Order shall be and remain the property of the Buyer; shall be subject to removal at any time upon the Buyer's demand; shall be used only in filling orders for the Buyer; shall be maintained in good order and condition and shall be clearly identified as the property of the Buyer. The Vendor assumes all liability for loss or damage to such property.

9. PATENT INDEMNITY The Vendor agrees to indemnify, hold harmless and defend the Buyer, its employees, directors, officers, Agents and students with respect to all claims, suits, actions and proceedings of actual or alleged infringements of any Letter, Patent, Registered or Industrial Design, Trademark or Trade Name, Trade Secret, Copyright or other protected right in any country resulting from any sale, use or manufacture of any Material delivered hereunder and to pay and discharge all judgments, decrees, and awards rendered therein or by reason thereof and bear all expenses and legal fees (including the Buyer's) associated herewith. The Buyer reserves the right to be represented in any such action by its own counsel at its own expense.

10. INDEMNITY The Vendor will indemnify, defend and hold the Buyer, its directors, officers, employees, agents and students harmless from any loss, expense, claim or damage including reasonable defense costs, arising from any claim or action based on any acts or omissions of the Vendor, its employees, servants, agents or subcontractors. The Buyer reserves the right to be represented in any such action by its own counsel at its own expense.

11. ASSIGNMENT/SUBCONTRACTING The Vendor shall not assign this Order, any rights under this Order or any monies due or to become due hereunder nor delegate or subcontract any obligations or work hereunder without the prior written consent of the Buyer. No purported assignment nor delegation by the Vendor shall be binding on the Buyer without such consent.

12. CANCELLATIONS The Buyer may cancel this Order in whole or in part, for no cause, upon written, FAX, or telex notice to the Vendor, effective when sent, provided such notice is sent at least fourteen (14) days prior to the delivery date specified on the face of this Order.

The Buyer may cancel this Order in whole or in part at any time for cause by written, FAX, or telex notice to the Vendor, effective when sent, in the event that the Vendor: (a) fails to comply with any term or condition of this Order including, but not limited to, delivery terms; or (b) appoints a receiver, liquidator or trustee in bankruptcy or other similar officer over any or all of its property or assets; or (c) files a voluntary petition in bankruptcy; or (d) has had filed against it an involuntary petition in bankruptcy which remains in effect for thirty (30) days; or (e) voluntarily ceases trading; or (f) merges with or is acquired by a third party; or (g) assigns any of its rights or obligations under the Order to a third party without the Buyer's advance written consent.

Upon the occasion of any one of the aforesaid and in addition to any remedies which the Buyer may have in Law or in Equity, the Buyer may also cancel this order or any outstanding deliveries hereunder by notifying the Vendor in writing of such cancellation and the Vendor shall thereupon transfer title and deliver to the Buyer such work in progress or completed material as may be requested by the Buyer. The Buyer shall have no liability to the Vendor beyond payment of any balance owing for Material purchased hereunder and delivered to and accepted by the Buyer prior to the Vendor's receipt of the notice of termination, and for work in progress requested for delivery to the Buyer.

13. RESCHEDULING The Buyer may without liability at least fourteen (14) days prior to the scheduled delivery date appearing on the Order defer delivery on any or every item under said Order by giving oral notice to the Vendor (confirmed in writing within ten (10) working days) of any necessary rescheduling.

14. PROPRIETARY INFORMATION/TITLE TO SPECIFICATIONS All written information obtained by the Vendor from the Buyer in connection with this Order and which is identified as proprietary, including, but not limited to, any specifications, drawings, blueprints and software programs, shall remain the property of the Buyer, shall be used by the Vendor only to the extent necessary for performance of this Order and shall not be disclosed to any third parties without prior written consent of the Buyer.

The Vendor shall not make or authorize any news release, advertisement, or other disclosure which shall deny or confirm the existence of this Order without prior written consent of the Buyer except as may be required to perform this Order.

15. SHIPPING, PACKAGING AND LABELING Materials must be shipped in accordance with Buyer’s instructions. Failure to follow the shipping method specified could result in chargeback of excess freight costs or $ 100 whichever is greater. All Material purchased hereunder must be packed and packaged to ensure its safe delivery in accordance with good commercial practice and where incorporated, the Buyer's packaging specification.

The Vendor shall mark on all containers, handling and loading instructions, shipping information, part number, purchase order number and item number, quantity in box, shipment date, and names and addresses of the Vendor and the Buyer. An itemized packing list must accompany each shipment. Each packing slip shall include; this Order number, quantity, item description, order date, shipping date and delivery address, but shall not include pricing information.

All shipments of hazardous materials under this Order shall comply with current U.S. Department of Transportation (DOT) regulations as published in 49 CFR 100-199, and the labeling shall meet the current U. S. Occupational Safety and Health Administration (OSHA) regulations as published in 29 CFR 1910. 1200, for the transporting and labeling of hazardous materials.

Material Safety Data Sheets (MSDS) shall be supplied with the first shipment of all hazardous materials, and these sheets shall be resubmitted if any changes or updates, as required, are made.

16. THE VENDOR AS AN INDEPENDENT CONTRACTOR The Vendor shall perform the obligations of this Order as an independent contractor and under no circumstances shall it be considered an agent or employee of the Buyer. The Terms and Conditions of this Order shall not, in any way, be construed as to create a partnership or any other kind of joint undertaking or venture between the parties hereto. The Vendor expressly waives any and all rights which may or may not exist to claim any relief under the Buyer's comprehensive insurance policy, worker's compensation or unemployment benefits.

17. INVOICING/PAYMENTS/SET-OFFS After each delivery of Material, pursuant to this Order, the Vendor shall send duplicate invoices including item number to the Buyer's Accounts Payable Department. All payments are in U.S. dollars. Determination of payment due date, whether under net or discount terms, will be based on the latest of (1) the date goods are received or services completed; (2) the date goods are scheduled to be shipped/received or services are scheduled for completion under the Purchase Order/Contract; or (3) date an accurate invoice is received. Unless a Specialty Products Company Buyer expressly authorizes early delivery of goods or services, payment for goods or services in advance of the contractual commitment date shall not be made prior to the contractual commitment date. Payment of invoice shall not constitute acceptance of Material ordered and shall be subject to appropriate adjustment, if the Vendor failed to meet the requirements of this Order. The Buyer shall have right at any time to set-off any amounts due to the Vendor, (or any of its associated or affiliated companies) against any amounts owed by the Buyer with respect to this Order or any subsequent Order or any other contractual agreement between the parties hereto unless such set-off violates local law or regulations.

18. INSURANCE AND STATUTORY OBLIGATIONS If any part of this Order involves the Vendor's performance on the Buyer's premises or at any place where the Buyer conducts operations, or with material or equipment furnished to the Vendor by the Buyer, the Vendor shall take all necessary precautions to prevent injury to persons or property during the progress of such work. The Vendor shall maintain public liability, personal injury, and property damage insurance and employer's liability and compensation insurance, in an amount determined by the Buyer to be appropriate, to protect the Buyer from said risks and from any statutory liabilities whatsoever arising there from. The Vendor shall produce evidence of such insurance upon request by the Buyer.

19. WAIVER The failure of the Buyer to insist in any instance upon the strict performance of any provision of this Order, or to exercise any right or privilege granted to the Buyer hereunder shall not constitute or be construed as a waiver of any such provision or right and the same shall continue in force.

20. NOTIFICATION OF HAZARDOUS PRODUCT The Vendor hereby agrees to notify the Buyer of any inherent hazard related to the Material being purchased herein that would expose the hazard during handling, transportation, storage, use, resale, disposal or scrap. Said notice shall be sent to the Buyer's Director of Purchasing and shall specify the product name and part number, the nature of the hazard, proper precautions that must be undertaken by the Buyer or others and any additional information that the Buyer should reasonably expect to know to protect its interest.

21. COMPLIANCE WITH LAWS By acceptance of this Order, the Vendor agrees to comply with the requirements of Executive Order 11246, as amended, relating to Equal Employment Opportunity; Executive Order 11701, relating to the Employment of Veterans, and the Rehabilitation Act of 1973 and their implementing regulations at 41 CFR 60-250 and 41 CFR 60-741. The Vendor also agrees to comply with the Fair Labor Standards Act and the Occupational Safety and Health Act, and all other applicable federal, state, county, and local laws, ordinances, regulations and codes in the Vendor's performance hereunder. Whether or not the Buyer provides a specification, if materials, services or containers furnished by the Vendor are required to be constructed, packaged, labeled or registered in a prescribed manner, the Vendor shall comply with the applicable federal, state, county and local laws, ordinances, regulations and codes. The Vendor further agrees to indemnify and hold the Buyer and its customers harmless from any loss or damage that may be sustained by the Buyer, by reason of the Vendor's failure to comply with any federal, state, county or local laws, ordinance, regulations and codes.

22. LAW OF THE CONTRACT This Order shall be governed by and interpreted in accordance with the laws of the State of Colorado.

Revision Number 3 – 07/20/2007

Online Training Portal Instructions

- Category: subpages

- Thursday, 06 January 2011 18:55

Online Training Portal Instructions

To access your course once you have purchased it at WheelAlignmentTraining.com

|

Privacy Policy

- Category: subpages

- Thursday, 06 January 2011 18:25

| |

Privacy Policy |

|

ONLINE PRIVACY POLICY AGREEMENT – Updated May 25, 2018 When we say “SPC” or “we” or “us” or similar words, we mean Specialty Products Company, a Colorado corporation. This Privacy Policy applies to personal information that we collect through the website at www.spcalignment.com; www.specprod.com or any subsidiary or affiliated website (each a “site”), mobile application, or otherwise in the course of our operations. We collect, use, and share information from and about you in order to offer and provide services described in one or more sites, apps, and/or other literature (the “Services”) and to operate our business. What information does SPC collect? The web site or mobile app collects various types, of information, such as:

Please rest assured that this site shall only collect personal information that you knowingly and willingly provide by way of completed forms and emails. It is the intent of this site to use personal information only for the purpose for which it was requested and any additional uses specifically provided on this site. SPC may collect and may make use of personal information:

With whom does SPC share information?

SPC does not now, nor will it in the future, sell, rent or lease any of our customer lists and/or names to any third parties.

If we ever transferred or consolidated our operations, we would transfer the information that we had collected to the transferee so that it could carry on these operations. All users and/or visitors to our website or mobile app have the option to discontinue receiving communication from us and/or reserve the right to discontinue receiving communications by way of email or newsletters. To discontinue or unsubscribe to our website or mobile app please send an email that you wish to unsubscribe to: custserv@specprod.com. If you wish to unsubscribe or opt-out from any third party websites, you must go to that specific website to unsubscribe and/or opt-out. Our websites and mobile apps contain links to affiliate and other websites. SPC does not claim nor accept responsibility for any privacy policies, practices and/or procedures of other such websites. Therefore, we encourage all users and visitors to be aware when they leave our website or mobile app and to read the privacy statement of each and every website or mobile app that collects personally identifiable information. The aforementioned Privacy Policy Agreement applies only and solely to the information collected by our website or mobile app. SPC shall endeavor and shall take reasonable precaution to maintain adequate physical, procedural and technical security with respect to our offices and information storage facilities as to prevent any loss, misuse, unauthorized access, disclosure or modification of the user's personal information under our control. What choices do I have about how my information is used and shared? We try to limit the collection, use, and sharing of information to just that information that we need for the purposes identified in this Privacy Policy. Accordingly, there’s not much use or sharing that we can restrict without the solution being to just discontinue the use of the Service. You can ask us to not use or share certain information, or to refrain from marketing to you, by contacting us using the information in the section entitled “How do I contact SPC?” We’ll tell you about your options. How does SPC communicate with me? We may contact you about goods or services that might be of interest to you, about your account, or the Services using postal mail, telephone calls, e-mail, text messages, or other electronic messages using any electronic address you have provided to us. You can manage your communication preferences by contacting us using the information in the section entitled “How do I contact SPC?“. What consents are you giving when you submit personal information to SPC through a site or another resource? By submitting your personal information in connection with a transaction or the use of this site or other resource, you are consenting and agreeing to the following things. 1. SPC may process your personal information in the United States or in such other location(s) as SPC reasonably deems appropriate and SPC may move that information from one place to another, including, but not limited to, into or, out of, places in which the law regarding personal information that applies in your current or home jurisdiction do not apply. 2. SPC may process your personal information for the purposes of answering your request, providing the goods, services, and/or software that you have ordered (or that have been ordered on your behalf), and communicating with you about such matters, goods, services, and/or software or similar matters, goods, services, and/or software. 3. Where the circumstances associated with your provision of your personal information indicate that ongoing communication is requested or contemplated (such as, but not limited to, when you sign up for a newsletter, event updates, or similar communications), SPC may process your personal information for such purposes within the reasonable scope of the kinds of contemplated communications. This consent is in addition to consent to the other collection, use, sharing, and other matters contained in this Privacy Policy. Do I have different rights if I’m a resident of California? Your California Privacy Rights: If you’re a California resident, California privacy law requires that we give you specific disclosures about our privacy practices, including telling you about the information we share with other third parties for their marketing purposes. You can request this information by contacting us using the information in the section entitled “How do I contact SPC?“. How long does SPC keep my information? We keep the information that we collect until we no longer need the information in order to provide the Services to you, conduct our operation, enable us to communicate with you, or satisfy our legal or contractual obligations. After that, we destroy the information or anonymize it. SPC reserves the right to update and/or change the terms of our privacy policy. If we change this Privacy Policy, we’ll post the revised Privacy Policy on the privacy portion of our website at www.specprod.com. We’ll post the revised Privacy Policy a reasonable amount of time ahead of when it will become effective. If you don’t want to continue under the revised Privacy Policy, you can terminate the Service and the revised Privacy Policy won’t apply. If you continue with the Service and don’t terminate, the new Privacy Policy will apply to you Through the use of this website or mobile application, you are hereby accepting the terms and conditions stipulated within the aforementioned Privacy Policy Agreement. If you are not in agreement with our terms and conditions, then you should refrain from further use of our sites. In addition, your continued use of our website or mobile app following the posting of any updates or changes to our terms and conditions shall mean that you are in agreement and acceptance of such changes. If you have any questions or concerns regarding the Privacy Policy Agreement related to our website, please feel free to contact us at the following email, telephone number or mailing address. |

Online Training Instructions

- Category: subpages

- Thursday, 06 January 2011 18:55

Online Training Portal Instructions

To access your course once you have purchased it at WheelAlignmentTraining.com

|

Basic Alignment - Alignment Angles

- Category: subpages

- Thursday, 06 January 2011 19:07

|

Alignment Angles What is your mechanic talking about when he says your toe angle is off? There are four basic alignment angles: |

|

|

Toe |

|

Camber |

|

Caster |

|

Thrust |

Basic Alignment - Tire Wear

- Category: subpages

- Thursday, 06 January 2011 19:07

|

Tire wear problems and solutions Your tires can tell you a lot about your alignment issues. |

|

|

Worn on one shoulder

|

|||

|

Worn on center of tire or both sides

|

|||

|

Feather edging or cupping

|

Basic Alignment - Benefits

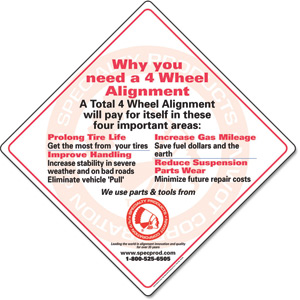

- Category: subpages

- Thursday, 06 January 2011 19:07

|

Benefits of a proper alignment A correct alignment has more benefits than prolonged tire wear. |

|

|

Prolong Tire Life

The reason most people get an alignment. With the high cost of tires, it is important to get the most out of your investment.

|

|

Improve Handling

Increase stability in severe weather and on bad roads. Can help to elminate vehicle 'pull'.

|

|

Increase Gas Mileage

Use less fuel and save fuel dollars. Great for the wallet and for the environment. |

|

Reduce Suspension Parts Wear

Minimize future repair costs. |

|

Improve Safety

Help eliminate unsafe drifting and unstable steering problems. |

Basic Alignment

- Category: subpages

- Tuesday, 26 October 2010 16:05

| What is alignment? Wheel alignment consists of adjusting the angles of wheels so that they are parallel to each other and perpendicular to the ground while ensuring the front and rear tires 'track' correctly. Often a tire shop or a mechanic will notice unusual tire wear and check the alignment to see if that is the cause of the improper wear. Sometimes a suspension component wears unusually which could also be a sign of a vehicle that is 'out of alignment'. If a customer complains of erratic handling or 'pulling' the mechanic will check the alignment to see if that is the reason for the customer's concern. Alignment angles can also be altered beyond the maker's specifications to obtain distinct characteristics. Racing, raising and lowering the vehicle (for appearance or handling), and off-road applications often mean that the different alignment angles will be set beyond what is 'normal' for the vehicle to met the customer's requirements. |

|

|

Types of Alignments A Two Wheel or Front End Alignment only aligns the two front wheels in relation to each other. This does not take into account the position of the rear axle. Mechanical gauges are normally used for this type of alignment. Almost all modern alignment is design to complete a Thrust Angle or Four Wheel Total Alignment.

A Thrust Alignment is usually performed on vehicles with a solid rear drive axle. Solid rear axle vehicles normally have no provisions for alignment adjustment. The alignment angles on all four wheels are read by the alignment equipment but only the front axle is adjusted. The front alignment angles are set parallel to the rear wheels thrust line. This is better than a two wheel alignment but there can still be issues with pulling and steering wheel position.

A Four Wheel Total Alignment is performed on vehicles with independent rear suspension that have alignment adjustment on both front and rear axles. Both axles are adjusted to the vehicle centerline. This insures the vehicle will track straight and the steering wheel will be centered. On all types of alignments the front and rear suspensions may require additional parts in order to make the proper alignment adjustments.

|

Check out these sections to find out more about why you may need a total wheel alignment.

|

A correct alignment has more benefits than prolonged tire wear - find out more here.

|

|

Your tires can tell you a lot about your alignment issues - find out more here.

|

|

What is your mechanic talking about when he says your toe angle is off? There are four basic alignment angles - find out more here.

|

Warranty Policy

- Category: subpages

- Friday, 02 October 2015 15:33

Specialty Products Fabrication

- Category: subpages

- Monday, 31 March 2014 17:38

|

|

|

|

4K Laser Cutter

Press Brake

Welding

|

|

Specialty Products Machine Centers

- Category: subpages

- Monday, 31 March 2014 17:38

|

|

|

|

Mazak Nexus 5000

Renishaw Probe for Extreme Tolerance Control |

|

|

Mori Seiki NTX2000

Multi-Spindle/5-Axis |

|

|

Mazak Hyper Quadrex 200MSY

Multi-Machine Redundancy High Pressure Coolant Extensive Tooling Robotics |

|

|

Mori Seiki NZ2000

Triple Turret/Live Tooling Multi-Spindle |

|

Specialty Products Services

- Category: subpages

- Monday, 31 March 2014 17:38

Services

Specialty Products Company has been a leading manufacturer for almost 50 years in Northern Colorado. Continually investing in the latest technology and equipment Specialty offers on-time, high-quality, cost-effective manufacturing solutions.

|

Manufacturing and Machine Shop Services

|

|

test

- Category: subpages

- Friday, 29 March 2013 14:41

')

.appendTo($(this));

});

('.imgText').live(

'mouseleave',

function(){

$(this).find('img').remove();

});

')

.appendTo($(this));

});

('.imgText').live(

'mouseleave',

function(){

$(this).find('img').remove();

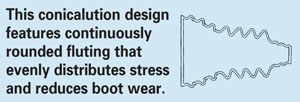

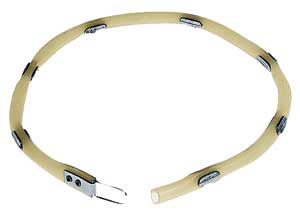

});CV Boots, Steering Boots & Tools

- Category: subpages

- Tuesday, 09 July 2013 15:45

|

CV Boots, Steering Boots & Tools

|

Brake Lathe Rotor Silencers

- Category: subpages

- Tuesday, 09 July 2013 15:45

|

Rotor Silencers

|

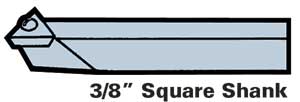

Brake Lathe Tool Holders

- Category: subpages

- Tuesday, 09 July 2013 15:45

|

Brake Lathe Tool Holders

|

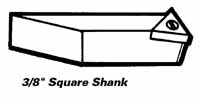

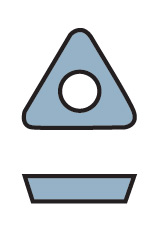

Brake Lathe Inserts

- Category: subpages

- Tuesday, 09 July 2013 15:45

|

Brake Lathe Inserts

|

500 Error

- Category: subpages

- Friday, 29 March 2013 14:41

500 Error

Internal Server Error

Our server doesn't recognize or is having difficulties with this page - check the URL to see if this is where you want to go.

404 Error

- Category: subpages

- Friday, 29 March 2013 14:41

404 Error

Not Found

The web page you are looking for does not exist - check the URL to see if this is where you want to go.

403 Error

- Category: subpages

- Friday, 29 March 2013 14:41

403 Error

Forbidden

You do not have the necessary permissions for this page - check the URL to see if this is where you want to go.

401 Error

- Category: subpages

- Friday, 29 March 2013 14:41

401 Error

Authorization Required

You do not have authorization for this page - check the URL to see if this is where you want to go.

400 Error

- Category: subpages

- Friday, 29 March 2013 14:41

400 Error

Bad Request

The most common reason for a 400 Bad Request error is because the URL was typed wrong or the link that was clicked on points to a URL with a specific kind of mistake in it, like a syntax problem. Check the URL to see if it is where you want to go.

Brake & CV

- Category: subpages

- Tuesday, 09 July 2013 15:45

|

Brake & CV

|

Terms, Warranties and Conditions

- Category: subpages

- Friday, 02 October 2015 15:33

TERMS AND CONDITIONS

SPC will use reasonable care to ensure that the information is accurate at the time it is added to the web site but cannot guarantee this and does not accept any liability to update the information. In addition, SPC does not accept any liability, howsoever arising, for the accuracy, completeness, use of or reliance on the information contained on this web site . The information may be changed by SPC at any time.

Competitor Crossover

- Category: subpages

- Thursday, 30 September 2010 15:19

|

{module [106]} |

Installer

- Category: subpages

- Tuesday, 26 October 2010 16:05

- If you want to stay competitive in today's high-tech automotive aftermarket SPC has the comprehensive Alignment Training Program for you.

- Go beyond the paper instructions and watch as our technicians walk you through the procedure and give helpful and time saving tips.

- SPC’s techs have answered many of the questions techs ask about installing our parts. You can find out tips and suggestions for individual parts in this section.

- Use our EZ Shim Calculator to help you line-up your EZ Shim correctly.

Distributors' Center

- Category: subpages

- Friday, 29 March 2013 14:41

Untitled Document

Distributors' Center

Sell more Specialty Products parts and tools with expanded distributor data along with retail and point of purchase aids.

Countermats & Sales Aids

|

Specialty Products Buyers Guide Need to check on country of origin or a list of vehicles that a specific part fits? At this Opticat link just type in the part number in the upper right hand corner and access that part's data. Opticat provides a quick reference for fitment, PIES part data, along with a complete buyers guide. Opticat is also our link to distributors for complete ACES and PIES data. For more contact Brandi Williams at Opticat.  |

|||

|

20023 |

2023 Source Book Our complete catalog filled with all the information installers need, including technical information, applications and more. This is the 'go-to' source for alignment techs, make sure your customers' have the latest edition.

Order Catalogs Here

|

||

|

20101 | Tire Store Table Tent Display Great for marketing at all tire sales locations! Remind your customer to extend the life of their tire investment! Heavy Card Stock Table Tent for countertop display. 4" x 8.5" size doesn't take up too much room, yet is a perfect conversation starter. |

||

|

20102 | xAxis™/Builders Series Display Kit Sell more SPC Performance Builder Series Components! This line of parts is specifically created for builders of off-road and race vehicles and often customers don’t know that these high quality components are easily available in the sizes/formats they need, right off the shelf! With our counter display you get a branded brochure holder with 15 Builder Series 12-page catalogs (#89990), a stair-step acrylic display featuring a xAxis Sealed Flex Joint, a rod end reciever and a weld-in receiver, along with a 11”x17” 2-sided counter mat (#20105 - below). |

||

|

20104 | Off-Road Adjustable Arm Counter Mat Create off-road Adjustable Front Control Arm sales with our 'Demand the Best' counter mat. This high quality counter mat features our popular adjustable upper control arms for Toyota, Ford, Nissan and Chevy. These arms are the industry standard and more and more off-road customers are adding this important component to their builds. 11” x 17” |

||

|

20106 | Heavy Duty Wheel Centering/Shims Counter Mat Create extra sales at the counter with this great teaching tool from SPC. This high quality, 2-sided counter mat explains the problems caused by off-centered wheels and the benefits of using our Wheel Centering Sleeves on one side and lists our popular Tandem Truck Shims and our Truck Axle Shims on the other. 11” x 17” |

||

|

|

20107 | "Benefits Of A Proper Wheel Alignment" Counter Mat Sell more alignments to your customers with this high quality counter mat which explains tire wear problems, alignment angles along with solutions and benefits of a proper four wheel alignment. This 2 sided mat describes the benefits of proper alignment and alignment angles on one side and has a quick reference guide for our EZ Cams™ on the other. 11" x 17" |

||

|

20108 | "Why Do You Need A Proper Alignment?" Poster All the alignment information from our popular Alignment Counter Mat (#20107), but in a large poster size. Perfect for fitting into standard retail store frames, this poster is a great selling tool for the front of your store. 22” x 35” |

||

|

20109 | Tire Display Insert Great for marketing at all tire sales locations! Remind your customer to extend the life of their tire investment! Heavy Card Stock Display for Showrooms. Can be used as a Tire Insert (16" to 18" Tires), Ceiling Hanger or Wall Poster. |

||

|

20110 | SPC Mouse Pad SPC's self-adhering Mouse Pad reminds counter people and installers to offer a Total Wheel Alignment to their customers, along with highlighting the benefits to the vehicle owner, such as prolonging tire wear, improve handling and safety and more. 7.5" x 8.5" |

||

|

20503 | EZ Cam™ EZ Sizer Magnet This magnet sticks on the installer's tool box, out of the way, and is a quick reference tool for measuring the right EZ Cam(TM) for the job! |

||

|

20504 | S.A.I. Diagnostic Guide Magnet This informative magnet trouble shooting guide sticks on the installer’s tool box, out of the way, and is a quick reference tool for understanding the effects of Steering Axis Inclination (S.A.I.) on alignment. This guide will help techs diagnose bent spindle assemblies and struts, determine if the top of the strut tower is correctly positioned, check if the control arms are bent and more. |

||

|

88034 | Traditional Installer Banner This 4' x 2.5' flag type installer banner is light weight and durable. Complete with grommets in all 4 corners, this banner is a great way to get out the word that your shop provides full alignment services, while informing the customer the benefits of having a full alignment service. |

||

|

88036 | Performance Installer Banner No hiding with this 4' x 2.5' banner. In black and red, this lightweight SPC Performance banner lets everyone know that you have the best in performance alignment parts. Durable, with grommets in all 4 corners, this banner is a great way to get out the word that your shop knows performance alignment and suspension tuning. |

||

|

Boxtop Flyer Promote Specialty Products with our popular Boxtop Promotion. Installers collect boxtops and redeem them for giftcards, SPC Gear, popular tools and more. Print out the PDF and get them in your installers' hands so they can start collecting box tops today. |

Coil Spring Spacer

- Category: subpages

- Monday, 29 June 2015 19:29

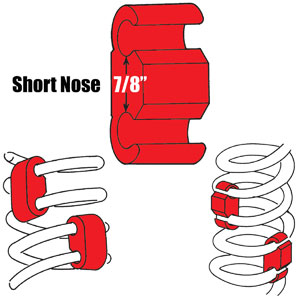

Coil Spring Spacers

|

Ride height can greatly affect alignment angles. Coil spring spacers can restore vehicle trim height and correct ride height issues associated with sagging springs and/or suspension modifications. Coil spring spacers allow shock absorbers and struts to operate through their normal range for longer life. Correct ride height will also improve vehicle ride, stability, and appearance. Spacers are aluminum and include one per package.

Note: When installed on front Short/Long Arm suspensions the vehicle height will usualy be raised 2-1/2 to 3 times the spacer thickness. On rear coil spring systems the vehicle height will usually be raised 1-1/4 to 1-1/2 times spacer thickness. Find a desired thickness from the options below to see the available spacers in that size.

We also have Coil Spring Stabilizers - see below. We have a limited Coil Spring Spacers application chart available for some vehicles. Click here to download.

|

3/8" Thickness

circumference than the 1102. |

1/2" Thickness

|

5/8" Thickness

|

3/4" Thickness

|

1" Thickness

|

1-1/2" Thickness

|

|

Proper alignment is impossible unless coil springs are operating at originally designed height. Two stabilizers are recommended per coil spring. If front stabilizers are rubbing against the spring well housing the stabilizer must be installed from the inside of the coil springs. Four per pack. Due to the curvature of some springs, two sizes may be required for the same spring (Example: 24700 on inside of coil, 24750 on outside). When measuring and installing stabilizers, one space should be skipped between coils. |

|

Stabilizer Heights – NARROW UNITS for small diameter (.58”) coil springs

|

Stabilizer Heights – REGULAR UNITS for average diameter (.63”) coil springs

|

Technical Support

- Category: subpages

- Monday, 17 January 2011 16:43

|

Technical Support Staff Our Technical Support Staff includes the most knowledgeable technicians in the alignment field. Our ASE certified technicians have years of experience, so you know that when you purchase Specialty Products, your alignment questions will be answered quickly and correctly. By combining our R&D staff along with our Training department you get to speak to some of the best minds in alignment technology.

Call our Technical Support Line at 1-800-525-6505.This Hotline is available to alignment technicians from Monday - Friday, 7:30 to 5:00 Mountain Time. |

AlignGuide™

- Category: subpages

- Friday, 29 March 2013 14:41

|

||||||||

|

Catalog Reader

- Category: subpages

- Thursday, 24 September 2015 22:28

Builder Series

- Category: subpages

- Friday, 29 March 2013 14:41

|

|

|

Features

Benefits

For more on our xAxis Sealed Flex Joints, including CAD models and Technical Data Sheets click here. |

Check out our new Builder Series/Off-Road flyer. Everything we have for this growing market is in this updated 12-page brochure. Our entire xAxis™ and tubular chassis line, everything JounceShock™ as well as selected alignment parts for off-road and lifted trucks. |

|

|